| Modèle | SLDM168-5 | SLDM168-6 | SLDM168-7 | SLDM168-8 | SLDM168-9 |

| Volume d'air (10^4 m³/h) | 9,6 ~ 12,0 | 11,52 ~ 14,4 | 13.44~16.8 | 15.36~19.2 | 17.28~21.6 |

| Surface totale du filtre (m²) | 2000 | 2400 | 2800 | 3200 | 3600 |

| G.W. (t) | 50 | 60 | 70 | 80 | 90 |

| Chambre | 5 | 6 | 7 | 8 | 9 |

| Sac filtrant Qté. | 840 | 1008 | 1176 | 1344 | 1512 |

| Résistance (Pa) | 1200~1600 | ||||

| Consommation d'air (m³/min) | 2~4 | ||||

| Densité de décharge (mg/N m³) | moins de 50 | ||||

| Fuite d'air (%) | moins de 3 | ||||

| Pression | 0,2 ~ 0,4 | ||||

Caractéristiques

Il y a 32, 64, 96 et 128 types de sacs filtrants dans chaque pièce. Le diamètre du sac filtrant est de 130 mm et la longueur du sac filtrant est de 2450 mm et 3600 mm.

Caractéristiques

La méthode de nettoyage hors ligne présente les avantages d'une grande énergie de nettoyage, d'un bon effet de nettoyage, d'une faible résistance du système, d'une longue durée de vie du sac filtrant et d'une efficacité élevée de dépoussiérage.

Application

Convient pour le dépoussiérage à haute concentration. La concentration de poussière du gaz d'entrée peut atteindre 1 000 g/Nm³. Il est non seulement largement utilisé dans les matériaux de construction, la métallurgie, la pétrochimie, l'alimentation, le fer et l'acier, le charbon, mais également utilisé pour purifier les gaz poussiéreux à température ambiante ou à haute température et formé dans l'électricité gaspillée et les poêles industriels et pour recycler les matériaux pulvérulents.

Introduction

Il présente les avantages d'un écoulement inversé de section et d'un dépoussiérage par impulsions, ce qui compense le manque d'intensité pendant la sous-salle et la réabsorption dans la poussière de nettoyage par impulsions. Le collecteur améliore l'efficacité, réduit considérablement la fréquence et utilise la vanne à impulsion immergée pour réduire la pression de l'air et la consommation d'énergie, prolonger la durée de vie de l'utilisation du sac filtrant et de la vanne à impulsion et améliorer considérablement les propriétés combinées.

Paramètres

| Paramètre technique | Modèle | ||||||||||

| SLDM160-2*5 | SLDM160-2*6 | SLDM160-2*7 | SLDM160-2*8 | SLDM160-2*9 | SLDM176-2*5 | SLDM176-2*6 | SLDM176-2*7 | SLDM176-2*8 | SLDM176-2*9 | ||

| Volume d'air (m³/h) | 23.04~28.8 | 27h65~34h56 | 32,5 ~ 40,32 | 36,86 ~ 28,8 | 41,47 ~ 51,84 | 25h34 ~ 31h84 | 30.41~38.02 | 35.48~44.35 | 40,55 ~ 50,68 | 45,62 ~ 57,02 | |

| Surface totale du filtre (m²) | 4800 | 5760 | 6720 | 7680 | 8640 | 5305 | 6336 | 7392 | 8448 | 9504 | |

| G. Poids (T) | 138 | 165 | 193 | 220 | 248 | 150 | 180 | 210 | 240 | 270 | |

| Chambre (pièces) | 10 | 12 | 14 | 16 | 18 | 10 | 12 | 14 | 16 | 18 | |

| Sac filtrant | Quantité (pièces) | 1600 | 1920 | 2240 | 2560 | 2880 | 1760 | 2112 | 2464 | 2186 | 3186 |

| Spécification (pouces) | F160*6000 | ||||||||||

| Valve d'impulsion | Quantité (pièces) | 100 | 120 | 140 | 160 | 180 | 110 | 132 | 154 | 176 | 198 |

| Résistance (Pa) | ≤1500 | ||||||||||

| Filtrage de la vitesse du vent (m/mi) | Si l'utilisateur en a besoin, selon le cas particulier, il est inférieur ou supérieur | ||||||||||

| La concentration d'entrée (g/N m³) | ≤100 | ||||||||||

| Taux de fuite d'air (%) | ≤3 | ||||||||||

| Pression (Mpa) | 0,3 ~ 0,5 | ||||||||||

Composition structurelle

• Boîte:

divisé en boîte supérieure, boîte centrale et boîte inférieure. Le boîtier supérieur comprend principalement un petit couvercle pour le sac filtrant, un sac de stockage d'air, une vanne d'impulsion, une vanne de levage et d'autres composants. Le sac de stockage d'air est utilisé pour stocker l'air comprimé, la vanne d'impulsion contrôle l'injection d'air comprimé et la vanne de levage est utilisée pour contrôler l'activation et la désactivation du flux d'air filtré ; la boîte du milieu comporte des sacs filtrants, des cages à sacs et des tuyaux d'entrée et d'échappement d'air. Le sac filtrant est le composant essentiel du filtrage de la poussière et la cage du sac est utilisée pour soutenir le sac filtrant ; la partie inférieure de la boîte et de la trémie à cendres comprend des colonnes, des trémies à cendres et des trous d'inspection, etc. La trémie à cendres est utilisée pour collecter la poussière filtrée, les colonnes jouent un rôle de support et les trous d'inspection sont pratiques pour l'entretien de l'équipement.

• Ensemble sac filtrant :

Il se compose d'un sac long et d'une cage à sac. Le matériau du sac long est diversifié et peut être sélectionné en fonction de différentes conditions de travail et caractéristiques de la poussière. Par exemple, le feutre aiguilleté en polyester peut être sélectionné dans des conditions de température normales, et la fibre de verre et d'autres matériaux peuvent être sélectionnés dans des conditions de température élevée. La fonction de la cage à sacs est de soutenir le sac filtrant afin qu'il puisse maintenir la stabilité de sa forme et de sa structure pendant le processus de filtrage et de nettoyage.

• Dispositif de pulvérisation pulsée :

y compris l'airbag, la valve d'impulsion, le tuyau de pulvérisation, etc. L'air comprimé est stocké dans l'airbag par le réservoir d'air. Lorsqu'un nettoyage de la poussière est nécessaire, la vanne à impulsion s'ouvre à l'intervalle de temps défini et l'air comprimé est instantanément pulvérisé dans le sac filtrant à travers la buse du tuyau de pulvérisation, provoquant l'expansion et la vibration rapides du sac filtrant, soufflant la poussière sur la surface du sac filtrant.

• Entrée et sortie :

L'entrée d'air est utilisée pour l'entrée de gaz contenant de la poussière et la sortie d'air est le canal d'évacuation du gaz purifié.

• Soupape de levage et soupape d'évacuation des cendres :

La soupape de levage est utilisée pour contrôler la commutation de l'état de filtrage et de nettoyage de chaque chambre, et la soupape d'évacuation des cendres est utilisée pour évacuer la poussière dans la trémie à cendres vers un emplacement désigné.

• Système de détection et de contrôle :

Il est composé de divers capteurs, contrôleurs, etc., qui sont utilisés pour surveiller les paramètres de fonctionnement du dépoussiéreur en temps réel, tels que la différence de pression, la température, le débit de gaz, etc., et contrôler automatiquement les opérations de nettoyage et de déchargement selon les paramètres définis.

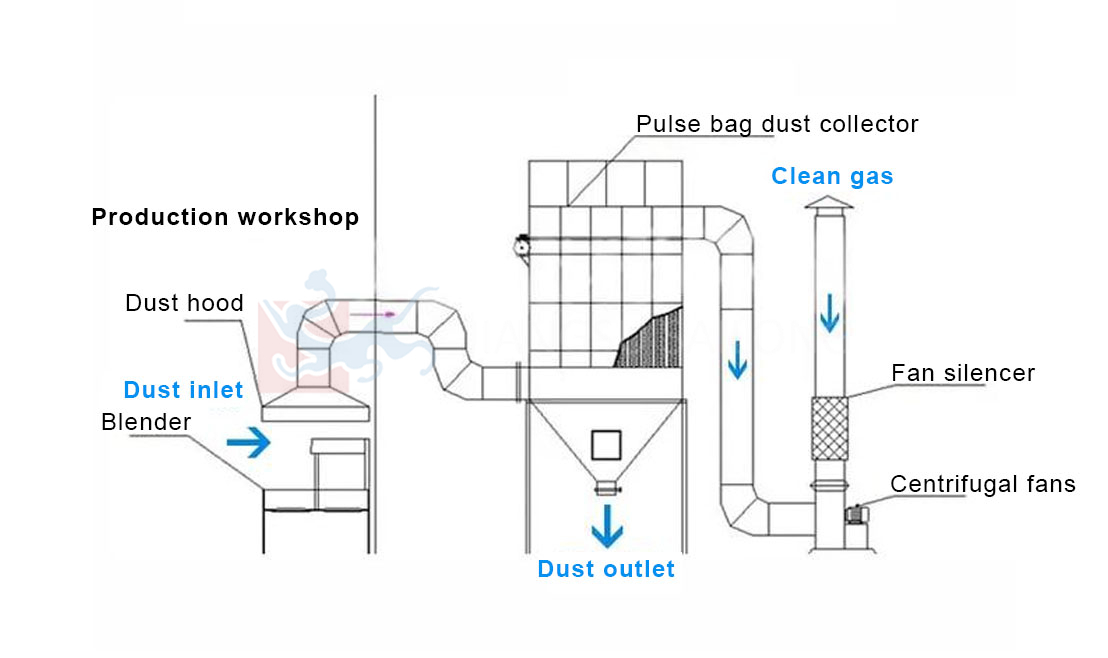

• Principe de fonctionnement :

Le gaz chargé de poussière pénètre dans la partie inférieure du boîtier central du dépoussiéreur depuis l’entrée d’air. Les grosses particules de poussière tombent directement dans la trémie à cendres en raison d'une collision inertielle, d'une sédimentation naturelle, etc. La poussière restante pénètre dans la zone filtrante de la boîte centrale avec le flux d'air et la poussière se dépose sur la surface extérieure du sac filtrant. Le gaz propre après filtration passe à travers le sac filtrant et est évacué par le boîtier supérieur, la soupape de levage et le tuyau d'échappement. À mesure que la condition de filtrage progresse, la poussière déposée sur la surface extérieure du sac filtrant continue d'augmenter, provoquant une augmentation progressive de la résistance du dépoussiéreur lui-même. Lorsque la poussière déposée sur la surface du sac filtrant atteint une certaine quantité, le dispositif de contrôle du nettoyage de la poussière envoie un signal pour fermer la vanne de levage d'une chambre du sac afin de couper le flux d'air filtrant de la chambre, puis ouvrir la vanne à impulsion électromagnétique. L'air comprimé du réservoir de stockage d'air passe à travers le sac gonflable dans une séquence de temps très courte à travers chaque vanne d'impulsion et la buse sur le tuyau de soufflage pour inciter l'air plusieurs fois la quantité de gaz d'injection à entrer dans le sac filtrant, formant une vague d'air, provoquant l'expansion et la vibration brusque du sac filtrant de l'embouchure du sac jusqu'au fond, et couplée à l'effet du flux d'air inversé, la poussière déposée à l'extérieur du sac filtrant tombe. Après avoir pleinement pris en compte le temps de dépôt de la poussière, la vanne de levage s'ouvre, le sac filtrant dans cette chambre à sac revient à l'état de filtrage et la chambre à sac suivante entre dans l'état de nettoyage, et ce cycle se termine lorsque le nettoyage de la chambre à sac suivante est terminé.

Avantages et caractéristiques

Dépoussiérage efficace :

• Bon effet nettoyant :

La méthode de nettoyage par jet pulsé est adoptée et l'intensité du jet est grande, ce qui peut éliminer efficacement la poussière sur la surface du sac filtrant, assurer l'efficacité de filtrage du sac filtrant et maintenir le dépoussiéreur à une efficacité de dépoussiérage élevée. Il a également un bon effet de capture des poussières dont la taille des particules est plus petite.

• Conception de sac filtrant long :

Le sac filtrant est plus long, ce qui augmente la surface filtrante et la capacité filtrante par unité de volume. Il peut traiter des gaz contenant de la poussière avec un grand volume d'air et convient à l'épuration des Gaz de combustion dans le cadre d'une production industrielle à grande échelle.

Fonctionnement stable et fiable :

• Conception structurelle raisonnable :

La structure globale est solide, la connexion entre les composants est étroite et peut résister à une pression de gaz et à une charge de poussière importantes. Il n'est pas facile de se déformer ou de s'endommager pendant le fonctionnement. • Contrôle automatique :

Équipé de systèmes avancés de détection et de contrôle, il peut surveiller l'état de fonctionnement de l'équipement en temps réel et effectuer automatiquement des opérations telles que le nettoyage et le déchargement selon les paramètres définis, garantissant ainsi le fonctionnement stable de l'équipement et réduisant les interventions manuelles et les erreurs de fonctionnement.

• Faible taux d'échec :

La sélection de matériaux et de composants de haute qualité, après une inspection et un contrôle de qualité stricts, garantit la fiabilité et la durabilité de l'équipement, réduit le taux de défaillance de l'équipement et réduit les temps d'arrêt et de maintenance.

Économie d'énergie et réduction de la consommation :

• Fonctionnement à faible consommation d'énergie :

La conception du système de nettoyage est raisonnable, ce qui peut réduire la consommation d'air comprimé et réduire le gaspillage d'énergie tout en garantissant l'effet de nettoyage. Dans le même temps, la perte de résistance de l'équipement est faible et la consommation d'énergie du ventilateur est également réduite en conséquence.

• Longue durée de vie du sac filtrant :

Des méthodes de nettoyage raisonnables et des matériaux de sac filtrant de haute qualité réduisent l'usure et les dommages du sac filtrant, prolongent la durée de vie du sac filtrant, réduisent la fréquence de remplacement du sac filtrant et réduisent les coûts d'exploitation.

• Large gamme d'applications :

Il peut être largement utilisé dans la purification des gaz de combustion dans les industries de l'énergie, de la chimie, de la métallurgie, des matériaux de construction, des mines et autres, et a un bon effet de traitement sur les gaz contenant de la poussière à haute température, à concentration élevée et à humidité élevée.

• Faible encombrement :

Comparés à d'autres types d'équipements de dépoussiérage à grande échelle, les dépoussiéreurs à sac long à impulsion et pulvérisation en ligne à grande échelle utilisent la technologie de pulvérisation en ligne, une structure compacte, un faible encombrement et sont plus pratiques à installer et à utiliser dans des endroits avec un espace limité tels que les usines.

• Entretien facile :

La conception structurelle de l'équipement est facile à entretenir et à réparer, et le démontage et l'installation de chaque composant sont relativement simples. En cas de panne de l'équipement, il peut être rapidement vérifié et réparé.

Paramètres

| Paramètre technique | Modèle | ||||||||||

| SLDM160-2*5 | SLDM160-2*6 | SLDM160-2*7 | SLDM160-2*8 | SLDM160-2*9 | SLDM176-2*5 | SLDM176-2*6 | SLDM176-2*7 | SLDM176-2*8 | SLDM176-2*9 | ||

| Volume d'air (m³/h) | 23.04~28.8 | 27h65~34h56 | 32,5 ~ 40,32 | 36,86 ~ 28,8 | 41,47 ~ 51,84 | 25h34 ~ 31h84 | 30.41~38.02 | 35.48~44.35 | 40,55 ~ 50,68 | 45,62 ~ 57,02 | |

| Surface totale du filtre (m²) | 4800 | 5760 | 6720 | 7680 | 8640 | 5305 | 6336 | 7392 | 8448 | 9504 | |

| G. Poids (T) | 138 | 165 | 193 | 220 | 248 | 150 | 180 | 210 | 240 | 270 | |

| Chambre (pièces) | 10 | 12 | 14 | 16 | 18 | 10 | 12 | 14 | 16 | 18 | |

| Sac filtrant | Quantité (pièces) | 1600 | 1920 | 2240 | 2560 | 2880 | 1760 | 2112 | 2464 | 2186 | 3186 |

| Spécification (pouces) | F160*6000 | ||||||||||

| Valve d'impulsion | Quantité (pièces) | 100 | 120 | 140 | 160 | 180 | 110 | 132 | 154 | 176 | 198 |

| Résistance (Pa) | ≤1500 | ||||||||||

| Filtrage de la vitesse du vent (m/mi) | Si l'utilisateur en a besoin, selon le cas particulier, il est inférieur ou supérieur | ||||||||||

| La concentration d'entrée (g/N m³) | ≤100 | ||||||||||

| Taux de fuite d'air (%) | ≤3 | ||||||||||

| Pression (Mpa) | 0,3 ~ 0,5 | ||||||||||

Ce site Web utilise des cookies pour vous garantir la meilleure expérience sur notre site Web.