Les séchoirs à cendres volantes sont en effet conçus pour traiter des sous-produits industriels tels que les cendres volantes, qui se caractérisent par leur faible densité apparente et leur teneur en humidité initiale potentiellement élevée. Cependant, la gamme de matériaux qu’ils peuvent traiter s’étend bien au-delà des cendres volantes. Tirant parti de leur principe de fonctionnement et de leur conception uniques, ces séchoirs sont également largement applicables pour le séchage de matériaux dans plusieurs industries.

Champ d'application

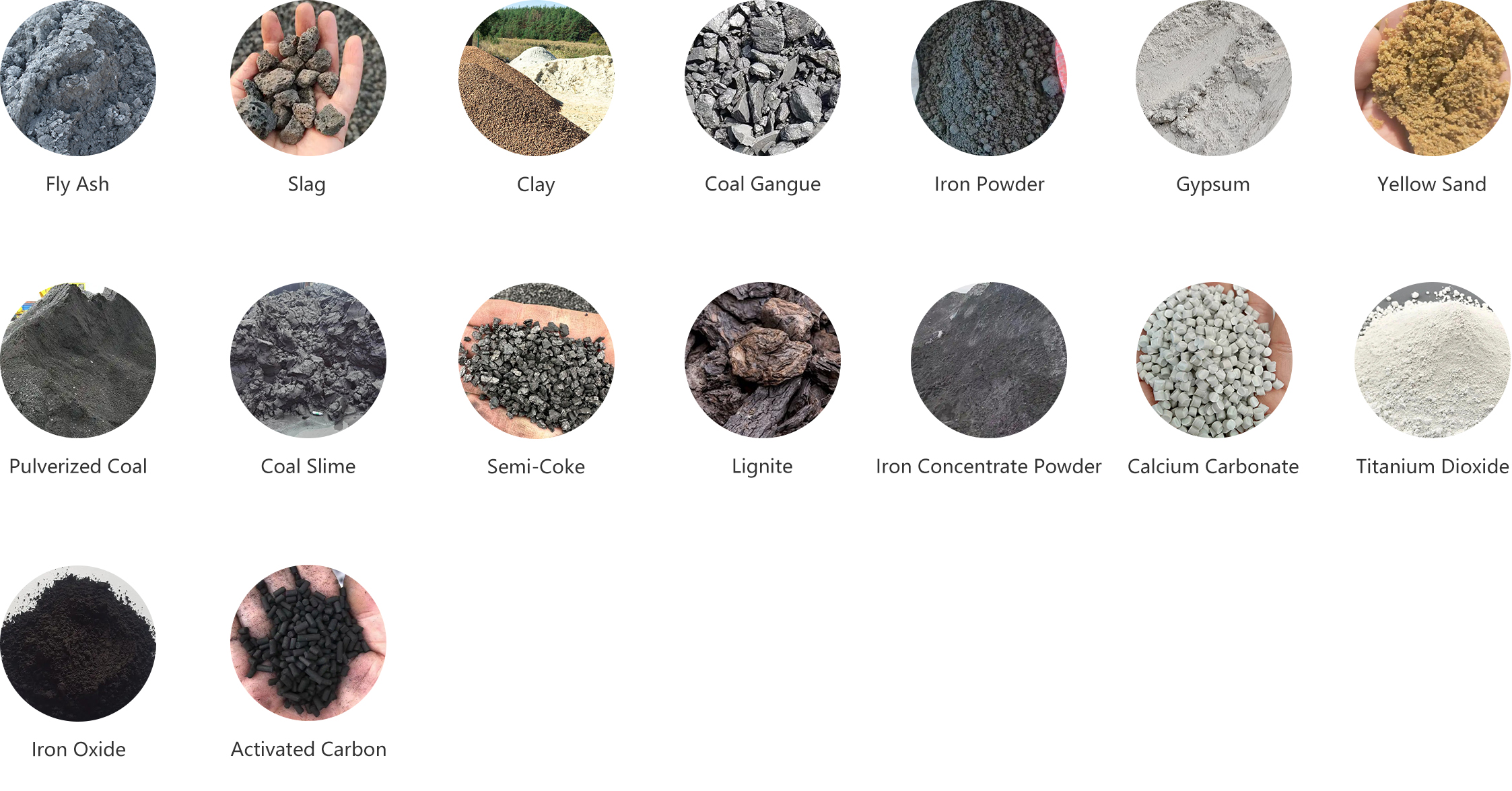

| Champ d'application | Exemples de matériaux spécifiques | Avantage |

| Industrie des matériaux de construction | Cendres volantes, scories, matières premières/additifs pour ciment (tels que argile, gangue de charbon, poudre de fer), gypse (y compris désulfogypse), sable jaune | Le processus exige une capacité de manipulation élevée et un fonctionnement constant pour atteindre une faible teneur en humidité finale (généralement ≤ 1 %), garantissant le respect des spécifications de formulation et de finesse pour la production de matériaux de construction. |

| Énergie électrique/industrie métallurgique | Charbon pulvérisé, bave de charbon, semi-coke, lignite, diverses poudres minérales (telles que la poudre de concentré de fer) | L'accent est mis sur les économies d'énergie et la réduction de la consommation, souvent grâce à l'utilisation de la chaleur perdue. L'équipement doit présenter une excellente résistance à l'abrasion et être capable de manipuler des matériaux adhésifs (par exemple, boue de charbon, gâteaux de filtration). |

| Produits chimiques et autres | Matières premières chimiques (telles que carbonate de calcium, dioxyde de titane, oxyde ferrique, oxyde de fer), charbon actif | Il existe des exigences spécifiques en matière de contrôle précis de la température et de pureté élevée du produit (pour éviter toute contamination). Les matériaux à traiter sont généralement à grains fins ou possèdent des propriétés physiques et chimiques particulières. |

Paramètres

Article | Unité | Modèle | |||

F3,2*8,0 | F3,6*8,0 | F3,8*10,0 | F4,0*12,0 | ||

Diamètre du cylindre extérieur | m | 3.2 | 3.6 | 3.8 | 4.0 |

Longueur du cylindre extérieur | m | 8.0 | 8.0 | 10,0 | 12,0 |

Volume du cylindre | m³ | 64.31 | 81.39 | 113.35 | 150,72 |

Vitesse du cylindre | tr/min | 4-10 | |||

La teneur en humidité initiale des cendres volantes | % | 20-25 | |||

Teneur en eau des cendres volantes | % | ≤2 | |||

Température d'entrée maximale | ℃ | ≤950 | |||

Capacité | ÈME | 20-25 | 25-35 | 40-50 | 50-55 |

Moteur | Y132-S-4 | Y160-M-4 | Y160-M-4 | Y280-S-4 | |

Pouvoir | kW | 11*4 | 15*4 | 90 | 110 |

Réducteur | XWD7-23 | XWD7-23 | 15-‖ | C'est incroyable‖ | |

Réducteur de rapport | 29 | ||||

Composition structurelle

• Cylindre sécheur :

Il s'agit du composant central, généralement constitué de matériaux métalliques, offrant une bonne résistance à la chaleur et une bonne étanchéité. La paroi intérieure du cylindre peut être équipée d'une plaque élévatrice ou d'une plaque élévatrice pour soulever et disperser en continu le matériau, augmenter la zone de contact entre le matériau et le flux d'air chaud et améliorer l'efficacité du séchage.

• Système de source de chaleur :

Fournit de la chaleur pour le processus de séchage. Les sources de chaleur courantes comprennent le charbon, le gaz naturel, les particules de biomasse, le fioul, etc. Le flux d'air chaud généré par la source de chaleur pénètre dans le cylindre de séchage par un tuyau ou un canal spécifique pour échanger de la chaleur avec le matériau.

• Dispositif de transmission :

comprend des composants tels que le moteur, le réducteur, l'accouplement et la roue de support. Le moteur fournit de la puissance et transmet la puissance à la roue de support via le réducteur et l'accouplement. La roue de support entraîne le cylindre de séchage en rotation, de sorte que le matériau continue de rouler et de se déplacer dans le cylindre.

• Dispositif d'alimentation :

Responsable du transport du mortier sec à sécher dans le cylindre de séchage. Généralement, il est nécessaire de garantir l’uniformité et la stabilité de l’aliment afin que le processus de séchage ultérieur puisse se dérouler sans problème.

• Dispositif de déchargement :

utilisé pour évacuer le mortier sec après séchage, généralement avec une bonne étanchéité pour éviter les fuites d'air chaud et le débordement de poussière.

collecter et traiter la poussière générée lors du processus de séchage, réduire la pollution de l'environnement et protéger l'environnement de travail et la santé des opérateurs. Les équipements courants de dépoussiérage comprennent les dépoussiéreurs à sacs, les dépoussiéreurs à cyclone, etc.

• Système de contrôle :

un système de contrôle automatique est utilisé pour surveiller et contrôler les paramètres de fonctionnement de l'équipement de séchage, tels que la température, la vitesse, la quantité d'alimentation, etc., afin d'assurer le fonctionnement stable de l'équipement et l'effet de séchage.

• Principe de fonctionnement :

une fois que le mortier sec et humide entre dans le cylindre de séchage à partir du dispositif d'alimentation, il est continuellement ramassé et dispersé par la plaque de levage ou la plaque de levage lorsque le cylindre tourne. Dans le même temps, le flux d'air chaud généré par le système de source de chaleur pénètre dans le cylindre, entre entièrement en contact avec le matériau et effectue un échange thermique. Sous l’action du flux d’air chaud, l’humidité du matériau s’évapore progressivement et se transforme en vapeur d’eau qui peut être évacuée du cylindre. Après une période de séchage, la teneur en humidité du mortier sec atteint la valeur requise et est évacuée du dispositif de déchargement.

Avantages et caractéristiques de l'équipement de séchage de mortier sec

Haute efficacité et économie d'énergie :

• Haute efficacité thermique :

Une conception structurelle avancée et de bonnes performances d'isolation thermique permettent au flux d'air chaud d'entrer entièrement en contact avec le matériau, de réduire les pertes de chaleur et d'améliorer l'efficacité thermique. Par rapport aux équipements de séchage traditionnels, il permet d’économiser beaucoup d’énergie.

• Forte adaptabilité du carburant :

En fonction des différents besoins de production et des conditions d'approvisionnement en combustible, vous pouvez choisir des combustibles appropriés, tels que le charbon, le gaz naturel, les pellets de biomasse, etc., pour réduire les coûts de combustible.

Bon effet de séchage :

• Séchage uniforme du matériau :

Grâce à la structure raisonnable du cylindre et à la conception du dispositif de levage, assurez-vous que le matériau peut être chauffé uniformément pendant le processus de séchage, évitez une surchauffe locale ou un séchage incomplet et assurez la qualité de séchage du mortier sec.

• Contrôle précis de l'humidité :

Il peut contrôler avec précision la teneur en humidité du matériau séché et, selon les différentes exigences du produit, contrôler la teneur en humidité dans une plage appropriée pour améliorer la qualité et la stabilité du produit.

Structure compacte :

• Faible encombrement :

Comparé à certains grands équipements de séchage, l'équipement de séchage de mortier sec a une structure plus compacte et un faible encombrement, ce qui convient à une utilisation dans des sites de production avec un espace limité.

• Installation facile :

La structure globale de l'équipement est simple, le processus d'installation est relativement simple et aucune infrastructure complexe ni équipement de levage à grande échelle n'est requis, ce qui peut raccourcir le cycle d'installation et réduire le coût d'installation.

Fonctionnement fiable :

• Équipements durables :

L'utilisation de matériaux de haute qualité et d'une technologie de fabrication avancée garantit la résistance à l'usure et à la corrosion de l'équipement et prolonge la durée de vie de l'équipement.

• Faible coût de maintenance :

L'équipement fonctionne de manière stable, le taux de défaillance est faible, les travaux de maintenance quotidiens sont simples et le coût de maintenance est faible.

Haut degré d'automatisation :

• Opération facile :

Équipé d'un système de contrôle automatique, l'opérateur n'a qu'à définir les paramètres pertinents et l'équipement peut fonctionner automatiquement, ce qui réduit considérablement l'intensité du travail et améliore l'efficacité de la production.

• Surveillance pratique :

Il peut surveiller l'état de fonctionnement de l'équipement et divers paramètres du processus de séchage en temps réel, tels que la température, l'humidité, la vitesse, etc., afin que l'opérateur puisse comprendre le fonctionnement de l'équipement à temps et effectuer les ajustements correspondants.

Bonne performance environnementale :

• Traitement des poussières :

Équipé d'un système de dépoussiérage efficace, il peut collecter et traiter efficacement la poussière générée pendant le processus de séchage, réduire les émissions de poussière et réduire la pollution de l'environnement.

• Les émissions de gaz d'échappement répondent à la norme :

Un traitement raisonnable du flux d'air chaud permet aux émissions de gaz d'échappement de répondre aux normes nationales de protection de l'environnement et de réduire l'impact sur l'environnement atmosphérique.

Paramètres

Article | Unité | Modèle | |||

F3,2*8,0 | F3,6*8,0 | F3,8*10,0 | F4,0*12,0 | ||

Diamètre du cylindre extérieur | m | 3.2 | 3.6 | 3.8 | 4.0 |

Longueur du cylindre extérieur | m | 8.0 | 8.0 | 10,0 | 12,0 |

Volume du cylindre | m³ | 64.31 | 81.39 | 113.35 | 150,72 |

Vitesse du cylindre | tr/min | 4-10 | |||

La teneur en humidité initiale des cendres volantes | % | 20-25 | |||

Teneur en eau des cendres volantes | % | ≤2 | |||

Température d'entrée maximale | ℃ | ≤950 | |||

Capacité | ÈME | 20-25 | 25-35 | 40-50 | 50-55 |

Moteur | Y132-S-4 | Y160-M-4 | Y160-M-4 | Y280-S-4 | |

Pouvoir | kW | 11*4 | 15*4 | 90 | 110 |

Réducteur | XWD7-23 | XWD7-23 | 15-‖ | C'est incroyable‖ | |

Réducteur de rapport | 29 | ||||

RELATED

RELATED

RELATED

RELATED

Ce site Web utilise des cookies pour vous garantir la meilleure expérience sur notre site Web.